YZ Series

Product Description

The iron-based amorphous alloy uses super quenching technology to actually cool the molten metal at a rate of one million degrees per second, forming an amorphous ribbon with a thickness of 25-30μm, which makes the atomic arrangement and combination have short-range order and long-range The amorphous alloy structure with order characteristics is completely different from traditional metal alloy materials in the microstructure. It is this alloy whose atoms are in an irregularly arranged amorphous structure, which gives it a narrow BH loop, high permeability and low loss. At the same time, the irregular arrangement of atoms in the amorphous alloy restricts the free passage of electrons. The resistivity is 2-3 times higher than that of crystal alloys, which is also beneficial to reduce eddy current loss.

The iron-based amorphous strip has an ultra-fine grain structure. With its high magnetic permeability, high saturation magnetic induction, low iron loss and excellent stability, it meets the needs of today's electronic products for high frequency, miniaturization, and energy saving. The need for direction development can replace silicon steel, permalloy and ferrite, and is widely used in electric power and electronic products.

• High magnetic permeability—(Max)>20´104 (no magnetic field annealing)

• High saturation magnetic induction-effectively reduce the volume of the magnetic sheet and reduce the thickness of the magnetic sheet

• Low loss-reduce eddy current loss, save power and improve efficiency

• Flexible material—effectively avoid the degeneration or fragmentation of the magnetic isolation sheet, and it is easy to use

• Temperature has little effect on performance-iron loss rate of change (120°C´200 hours) <15%

1) Storage temperature range

From + 0 ℃ to + 40 ℃ Humidity range 15%RH --- 70% RH

(2) Operating temperature range From-20 ℃ to + 105 ℃ After connection, external force (bending, tension, machine impact, etc.) must not be added.

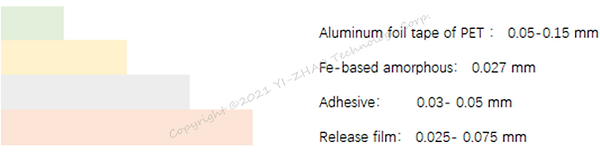

Product specifications

YZ-1-01、YZ-2-01、YZ-3-01

Applications

1. Electromagnetic mask for digital tablets, amorphous electromagnetic mask foil for digital electronics

2. High-power switching power supply, reactor chip

3. Ring filter inductor, open inductor core

4. Intermediate frequency transformer core, power frequency distribution transformer core, saturation reactor, pulse compressor core

Product specifications

Product Features

Product test method

Measurement method

According to the microwave anti-wave reflection attenuation and measurement method customized by our laboratory, this method refers to the method in the appendix [1] of the US military regulation MIL-A-17161D* (the measurement method is not the direct transmission of the signal and the direct absorption contact)

Measurement range 3~18GHz reflection attenuation characteristics (expressed by db loss value)

Generally speaking, -3db means 50% absorption, -6db means 75% absorption, -10db means 90% absorption, -20db means 99% absorption.

Measuring Instruments

HP8500B Vector Network Analyzer

Measurement unit

The product of the microwave reflection attenuation measurement report of the Microwave Measurement Laboratory of the Institute of Chemistry, Zhongshan Academy of Sciences, Taiwan

Magnetic properties

50 HZ loss curve

Sample size 300*30mm

The test method is 25mm Epstein square circle

50Hz excitation power curve

Sample size 300*30mm

The test method is 25mm Epstein square circle

High frequency loss

The sample size is 38*34*142mm (OD*ID*H), and the performance testing equipment is an AC magnetic characteristic analyzer

Permeability range of different materials

Test frequency: f=1KHz

Reliability test

Product test report

Non-fine magnetic-nanocrystalline Q value